Beer industry is "high-investment, high-consumption, high-emissions, and difficult to recycle". If low-carbon environmental protection is not in place, it will cause great pollution to the world's climate, and will encounter green trade barriers, which will cause great difficulties for the future competitiveness of beer companies. With the extensive development and application of high technology and the increasing level of people's living consumption, people's requirements for beer taste, variety and quality are constantly improving, prompting beer manufacturers to continuously reform the original old processes, adopt new technologies and new processes, reduce energy consumption costs, and improve beer quality, and beer filtration is the focus of technological innovation.

Filtration is an important part of improving product quality in the beer production process, and it is directly related to the stability, appearance and taste of beer quality. The traditional filtration method uses diatomaceous earth filtration combined with precision filter element filtration. Although some impurities can be removed, the removal of colloids, yeast, bacteria, and microorganisms is not complete. The filter element is clogged quickly, and pasteurization is required. Due to high-temperature heat treatment, some aromatic substances are oxidized and lost, which seriously affects the original flavor of beer. During the storage of draft beer, microorganisms cause spoilage and turbidity of protein.

Membrane filtration technology is characterized by its high efficiency, no phase change, low energy consumption, no three wastes, low investment, and easy automation. It can be applied to aseptic filtration in the beer industry, beer recovery from yeast liquor, and alcohol-free beer production.

Beer membrane filtration system can remove microorganisms and other turbidity in draft beer, maintain the aroma and taste of fresh beer, so as to achieve the simultaneous completion of sterilization/turbidity removal, avoid the thermal process in processing, and more completely retain all the nutrients of the beer. It reduces and solves the discharge of pollutants, and enables the comprehensive utilization and recycling of effective ingredients. At the same time, it can remove yeast and other bacteria and prevent the generation of sediment.

Membrane filtration technology has incomparable advantages over diatomite filtration

1. Membrane filtration technology is in a closed state for both filtration and cleaning, which can realize automatic and continuous production, greatly improving production efficiency;

2. Environmentally friendly; little beer loss, clean production can be realized;

3. It can replace the secondary filtration of diatomite and fine filter, greatly reducing production costs;

4. High degree of automation and convenient maintenance;

5. Suitable for filtering different kinds of beer

Yeast sediment refers to the yeast that remains in the fermentation tank when the wine is produced, which contains beer (sediment beer). If 1000L beer has 3L recovered yeast and sediment beer, the yeast sediment is 1.5-2% of the beer volume. The amount of sediment beer recovered from the yeast is about 1% of the total finished beer, and in the membrane filtration system, the beer with a very thin concentration is filtered through the membrane surface, and the yeast continues to circulate. Membrane filtration does not require filter aids, and has been increasingly used to recover beer from yeast. The recovered beer is of high quality, without the increase of dissolved oxygen, and the beer is clear, which can recover good quality beer and improve economic efficiency.

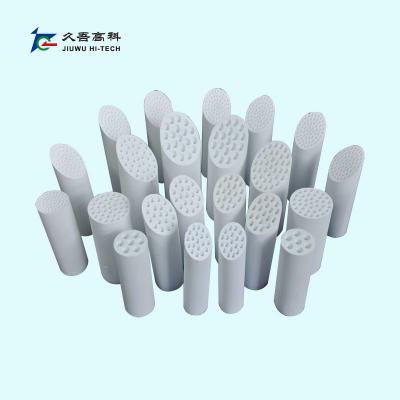

The filtration accuracy of ceramic membrane covers microfiltration and ultrafiltration. The filtration pore size of the microfiltration membrane ranges from 0.05μm to 1.4μm. The filtration accuracy of the ultrafiltration membrane can range from 10KDa to 50KDa. Based on the viscosity and suspension of the materials, you can select membranes with different pore diameters to achieve the purpose of clarification and separation. It comes with a CIP system dedicated to the cleaning of ceramic membranes with cross-flow filter aids, which is ready to use. Clean in time after each filtration to maintain membrane flux and use life. The nano membrane technology adopts low-temperature filtration, which can directly filter bacteria, improve the clarity and sensory degree of beer, make the flavor and taste more delicious, solve the generation of sediment, and extend the shelf life of beer. Ceramic membrane has the characteristics of high temperature resistance, chemical corrosion resistance, high mechanical strength, strong antimicrobial ability, large penetration, strong cleanability, narrow pore size distribution, good separation performance and long service life. It has been used in the chemical and petrochemical industries. The separation process in the fields of food, biology and medicine has been successfully applied.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español