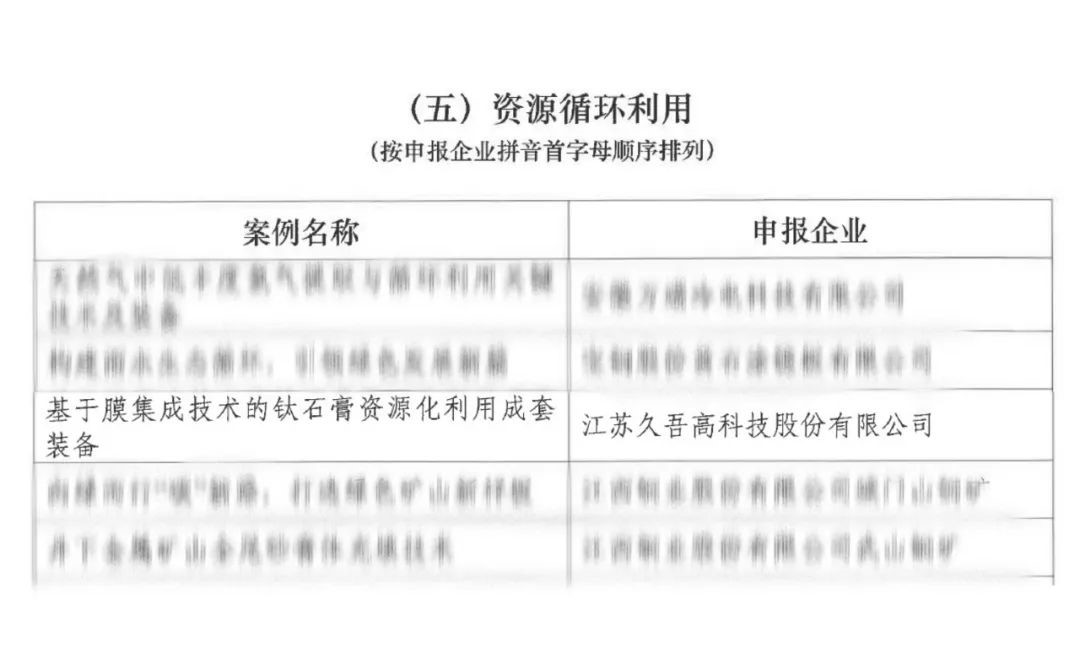

Recently, the China Enterprise Confederation and the China Enterprise Directors Association jointly released the "2024 Excellent Practice Cases of Green and Low-Carbon Development for Enterprises". A total of 452 company cases were collected for this selection, and 271 cases were shortlisted based on four criteria: technological advancement, managerial innovation, practical effectiveness, and promotional demonstration. Jiuwu Hi-Tech's submission of "Equipment for Resource Utilization of Titanium Gypsum Based on Membrane Integration Technology" addressed the issue that titanium gypsum could only be disposed of by stacking and landfilling, and successfully won the recognition. It was also the only company in Jiangsu Province to be shortlisted in the field of resource recycling.

Over 90% of titanium dioxide in China is produced by the sulfuric acid method, which inevitably generates a large amount of acidic wastewater (containing 2%~5% sulfuric acid) during the production process. The acidic wastewater mainly comes from titanate acid washing, acid decomposition, calcination waste gas cooling washing wastewater, as well as acidic wastewater from equipment cleaning and operation sites. Currently, limestone and lime (or carbide slag) are generally added to neutralize the acidic wastewater, producing industrial sludge with dihydrate gypsum as the main component, known as titanium gypsum (also referred to as red gypsum, yellow gypsum).

(Temporary storage yard for titanium gypsum of a company)

Due to the high impurity content in titanium gypsum, its strength is very low or even non-existent after being calcined into hemihydrate gypsum, so its application in gypsum building materials is minimal. Additionally, as an additive for cement retarder, its amount cannot be too much, as it can reduce the strength of cement at 3 and 28 days. Therefore, most titanium gypsum is currently stored in slag yards or scattered across various local environments. The cumulative amount of storage has reached over a billion tons over the years, occupying a lot of valuable land and consuming substantial construction and maintenance costs for the storage yards.

Jiuwu Hi-Tech, adhering to the philosophy of "source control" of environmental pollution, has innovatively developed a titanium gypsum crystal growth agent, combined with mature membrane purification technology, crystal growth and neutralization technology, and low-temperature slow calcination technology. They developed the MCM Titanium Gypsum Resource Utilization Process Technology, solving the issues of traditional titanium gypsum being fine crystal, highly impure, and high water content, and converting it into high-value-added building gypsum powder after calcination. From the source, the acidic wastewater from titanium dioxide production is transformed into building gypsum powder, achieving sustainable and green development of titanium dioxide enterprises.

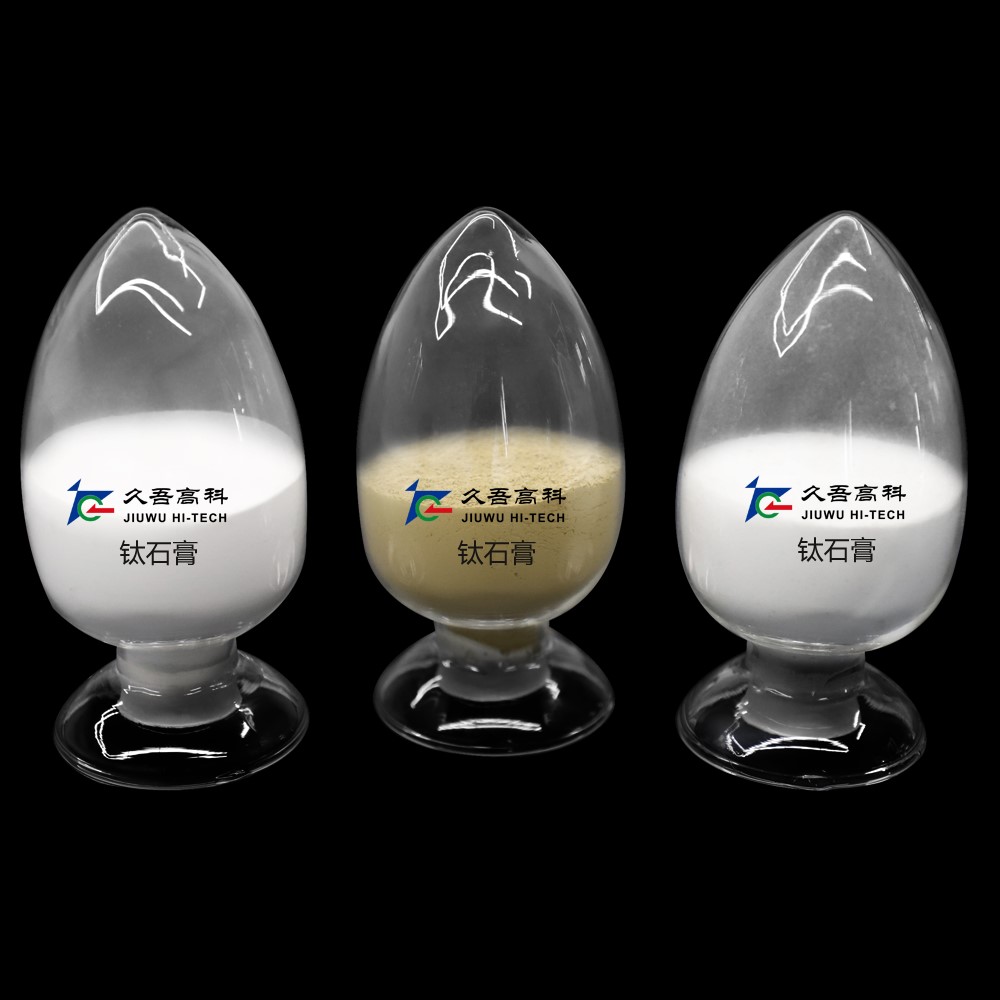

Solves the issues of low-grade, high impurity content, and poor color of titanium gypsum

Addresses the issues of small crystal size and high free water content in titanium gypsum

Successfully converts titanium gypsum into α high-strength gypsum and β building gypsum

Taking 20 production lines as an example, each production line processes 500,000 tons of titanium gypsum annually. The 20 production lines collectively reduce the discharge of titanium gypsum by about 10 million tons per year, improving the comprehensive utilization rate of titanium gypsum from the traditional 10% to over 50%.

Based on the storage and landfill fee of 40 yuan per ton for titanium gypsum, it saves approximately 400 million yuan in storage, landfill, and environmental construction expenses each year, significantly reducing the waste of land resources and having remarkable environmental benefits.

Taking a single production line project with an annual capacity of 130,000 tons of β building gypsum as an example, with a total investment of about 44 million yuan, it can reduce the titanium gypsum generated by current production processes of titanium dioxide enterprises by about 300,000 tons per year.

Based on the low market price of 350 yuan per ton for building gypsum powder in the Jiangsu, Zhejiang, and Shanghai areas, the annual sales revenue would be 45.5 million yuan, with an investment payback period of about 3.25 years.

This product's process couples membrane separation technology, crystal growth and neutralization technology, and low-temperature slow calcination technology. By implementing the source control concept, it purifies the acidic wastewater produced in the titanium dioxide production process and calcines the titanium gypsum into building gypsum powder. This can be used as a raw material for products such as lightweight plastering mortar, gypsum-based self-leveling, and ceramic membrane gypsum, enhancing the added value of the products and solving the practical problem of titanium gypsum being only stored and landfilled.

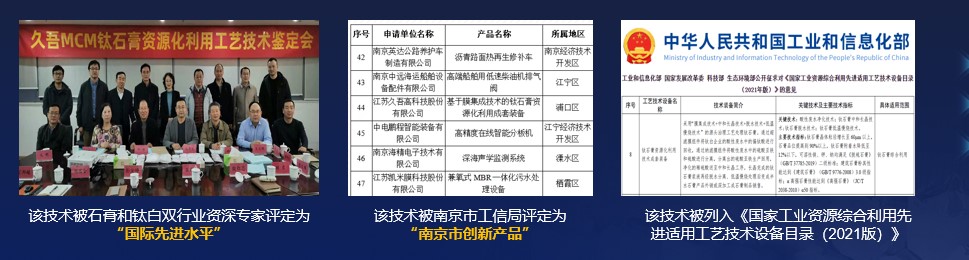

This technology has obtained a national authorized patent (ZL202022398837.X). Product performance has been evaluated by senior experts in both the gypsum and titanium dioxide industries as "international advanced level" and has been recognized as an "Innovative Product of Nanjing City" by the Nanjing Municipal Bureau of Industry and Information Technology. It achieves harmless, reduced, and resourceful treatment of titanium gypsum, being the first of its kind in China and can address the green development issue of sulfuric acid titanium dioxide in China.

Being shortlisted for the 2024 Excellent Practice Cases of Green and Low-Carbon Development for Enterprises is a high recognition of Jiuwu Hi-Tech's efforts and achievements in the field of green and low-carbon development, and it also serves as an encouragement for the company's continuous exploration and innovation on the path of green and low-carbon development. In the future, Jiuwu Hi-Tech will continue to provide customers with green and advanced membrane integration technology solutions, promote the experience of membrane integration technology in relevant industries, expedite the application of core processes for the green transformation of industries, and make greater contributions to the green and low-carbon transformation and development of enterprises.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español