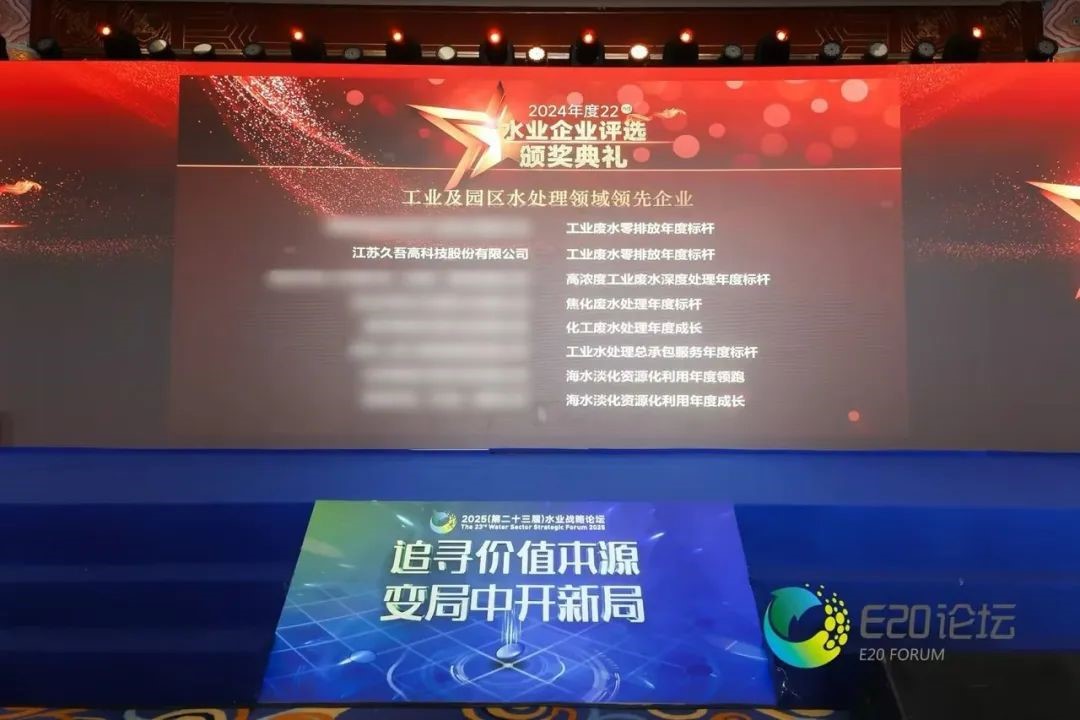

On March 28, 2025, the 2025 (23rd) Water Industry Strategy Forum, hosted by E20 Environmental Platform, opened in Beijing. This forum, with the theme "Pursuing Value Origins, Creating New Paradigms in Changing Situations," focused on the new path of high-quality development in the water industry. By constructing a collaborative innovation platform among government, industry, academia, and research, the forum deeply analyzed industry pain points and explored innovative development paths, providing systematic solutions for companies to tackle multiple challenges such as stock competition, policy adjustments, and technological iterations.

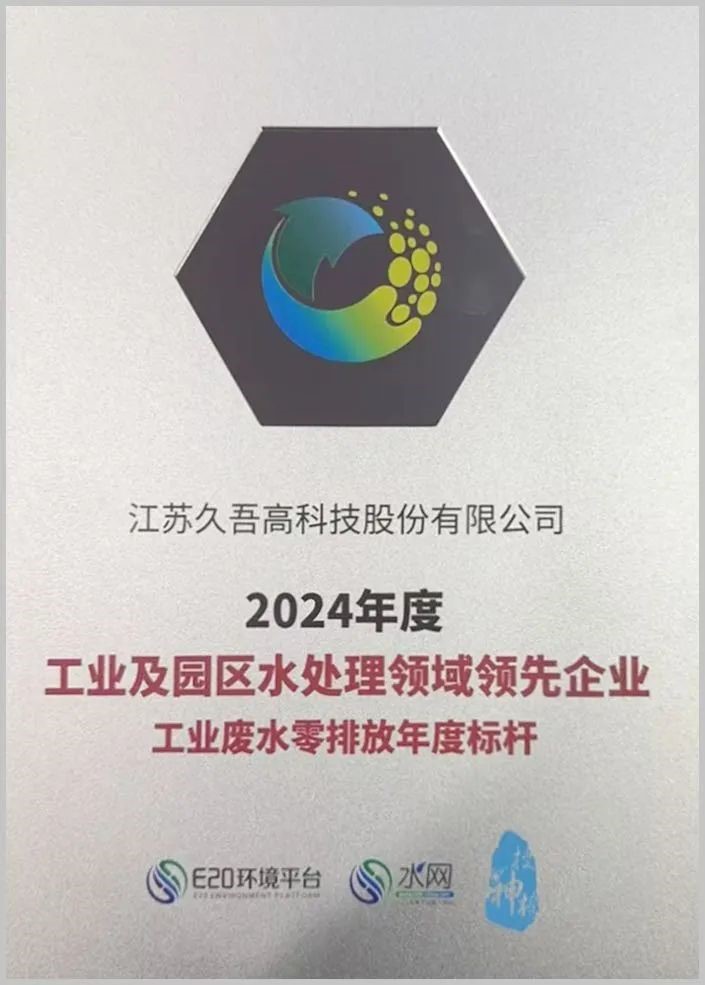

At the highly anticipated annual awards ceremony, Jiuwu Hi-tech won the honor of "Annual Benchmark Enterprise for Zero Industrial Wastewater Discharge" for its outstanding technological strength and rich engineering experience in the field of zero industrial wastewater discharge, fully demonstrating the company's leading position in environmental technology innovation.

To respond to the national strategy of protecting the Yangtze River, Jiuwu Hi-tech participated in the EPC general contracting project for the wastewater pretreatment, water reuse, and desalinated water complete sets of devices in a Nantong project for relocating and upgrading a nitrile rubber facility with a capacity of 40,000 tons per year (hereinafter: the project). The project's wastewater mainly includes production wastewater and domestic wastewater, including newly built sewage treatment, water reuse, and supporting facilities. Using the EPC general contracting model, this project was also shortlisted for the "2025 Water Industry Excellent Case Compilation."

This project uses mature and reliable wastewater biochemical treatment technology to achieve standard discharge of industrial wastewater, which can be used as the raw water for water reuse. Jiuwu Hi-tech uses advanced membrane separation technology to maximize water resource recovery, reduce reliance on fresh water sources, and minimize water resource waste. At the same time, it meets the demand for desalinated water supply necessary for production, helping enterprises achieve sustainable development. By optimizing water resource allocation, alleviating water resource shortages, reducing wastewater discharge, protecting the water ecological environment, promoting industry water conservation and emission reduction, and achieving a win-win situation for both economy and environment, the project drives sustainable societal development.

The project uses an "ultrafiltration + reverse osmosis dual-membrane system" as the main component, significantly reducing the use of fresh water resources. It demonstrates the efficient practice of circular water resource utilization for chemical enterprises and provides a water-saving model that can be referenced by enterprises facing water resource shortages, guiding the industry to improve water resource utilization efficiency. At the same time, it also reduces wastewater discharge, decreases the impact on ecosystems, and promotes the healthy circulation of ecosystems.

Wastewater Pretreatment Process: softening + coagulation sedimentation + hydrolysis + A/A/O + MBR, compliant discharge/water reuse.

Water Reuse Process: UF + single-stage RO, water reused/desalinated water production, brine discharge.

Desalinated Water Process: activated carbon filter + two-stage RO, water reused, concentrated brine returned to the front end.

Advanced Membrane Technology: Uses highly cross-linked anti-fouling reverse osmosis membranes to enhance hydrophilicity and charge properties, extend lifespan, and reduce O&M costs.

Superior Water Quality: Deep removal of organics, salts, and microorganisms (desalination rate >99%), resulting in high-standard reuse water and achieving circular utilization.

Compact Integrated System: Integrates biological treatment and membrane technology, small footprint, simplified piping, and reduces both investment and operational risks.

Intelligent Flexible Adaptation: Compatible with multiple water sources, flexible parameter adjustment, ensuring stable water quality.

High Efficiency and Energy Saving: Optimizes pump groups and energy recovery technology, significantly reducing energy consumption.

The project that Jiuwu Hi-tech participated in, as an advanced environmental demonstration project in the industry, provides valuable technical and management experience for other nitrile rubber production enterprises, promotes the coordinated development of related industries, drives infrastructure improvement, and enhances public services. It elevates the corporate image and supports public welfare, comprehensively promoting local social progress and development. It serves as an advanced environmental demonstration project within the industry, providing experience for other enterprises to reference, promoting the entire industry's transition to green and low-carbon practices.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español