Membrane technology is honored as the water treatment technology in 21st century, playing important roles in both seawater desalination and wastewater regeneration.

At present, reverse osmosis (RO) technology has become one of the most important methods of desalination of seawater.

Pretreatment is an indispensable step of RO technology.

The disadvantages of the traditional method of desalination water treatment

A. can not completely remove colloidal and suspended substances

B. water quality fluctuations easily

C. reduce water-yielding capacity and service life.

The application of ceramic membrane filtration as a pretreatment process has the following characteristics

A. Water turbidity <0.1 NTU, SDI15 <2.0

B. Improve the quality of reverse osmosis membrane influent

C. Extend the service life of RO membrane elements

D. Reduce chemical agents consumption

E. Small footprint

F. Less investment

The main equipment of RO consists of high-pressure pump, RO membranes, energy recovery, ceramic membrane filtration equipment includes feed unit, ceramic membrane loop, CIP unit, control unit. No matter seawater, brackish water, no matter large scale, pilot scale and lab, we offer R & D design, equipment manufacturing, construction, operation and maintenance.

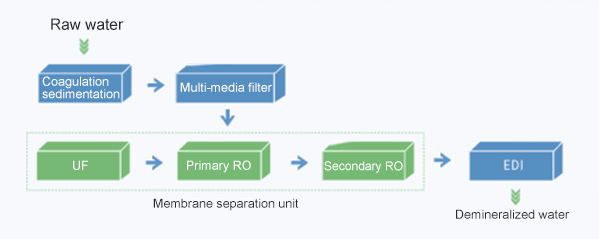

Demineralized water

The raw water for desalinization includes surface water, ground water and municipal sewage. Raw water contains various pollutants such as microorganisms, organic matter, suspended matter and colloids. In order to meet the requirements of make-up water, the boiler feed water needs treated by: coagulation, sedimentation, filtration, softening. The quality, hardness and alkalinity of the water source should meet the standards to ensure the steam quality of the boiler, reduce maintenance and extend the service life. The following membrane integration process reduces the dependence of boiler make-up water on municipal tap water while reducing the operating costs of the power plant.

The advantages of the ceramic membrane process:

A. Water quality is stable by continuous operation.

B. The system runs reliably and stably

C. Low running cost

D. Small land occupation

E. High auto operation

F. Easy operation and maintenance

G. Safe use

H. No sewage discharge

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español