Industrial wastewater has been hailed as one of the most difficult "bone" to bite in the water treatment industry due to its complex composition and variable nature. Industrial wastewater generally has particularities such as acidity and alkalinity, and contains organic solvents. Traditional organic membranes are usually difficult to adapt to such harsh and complicated conditions; and ceramic membrane can fully and stably operate in these extreme environments for a long time due to the advantages of their materials.

In industries such as mechanical processing and metal calendering, oily wastewater such as emulsion wastewater generated during the cutting and grinding of machine parts is difficult to treat with conventional methods. The hydrophilic and oleophobic properties of ceramic membranes are required to effectively remove oil from industrial wastewater. The degreasing rate of the emulsified oil wastewater after being treated by ceramic membrane can reach more than 99%, which can realize the reuse of oil and water.

Oily wastewater is a kind of high-concentration and difficult-to-degrade wastewater that is currently difficult to treat. At home and abroad, physical and chemical treatment methods such as air floatation, adsorption, biochemistry, and chemical methods are often used. The effluent cannot be stably met and there are many shortcomings such as a large consumption of reagents, high operating costs. It is difficult to achieve the ideal treatment effect.Ceramic membrane ultrafiltration technology has outstanding advantages such as strong acid and alkali resistance, high mechanical strength, uniform pore size distribution, good temperature resistance, and long service life. It has attracted extensive attention at home and abroad, and has been applied in many fields. Therefore, in oily wastewater treatment, the first consideration is to use inorganic ceramic membrane ultrafiltration membrane cross-flow operation, which has the advantages of large membrane flux, anti-pollution, and long-term operation without clogging. It can solve the problems that conventional treatment techniques are difficult to solve.

The ceramic membrane was used to treat the oil-bearing wastewater of a steel rolling mill. The parameters of the cross-flow filtration operation were determined through tests as follows: pressure 0.1MPa, flow rate 15m/s, permeability can be stabilized at 130L/h.m2, and the effluent quality can meet the discharge requirements. You can see them in the table below.

| Item | COD(mg/L) | PH | Oil(mg/L) | Ammonia(mg/L) | SS(mg/L) |

| Oily wastewater | 1000-3000 | 6-9 | 2000 | 100 | 200-400 |

| Effluent requirement | ≤100 | 6-9 | 8 | ≤10 | ≤10 |

| Treated water quality | ≤40 | 7 | 6 | 5 | 8 |

Ceramic membrane products has the following advantages in the treatment of oily wastewater:

Therefore, the application of ceramic membranes in the petrochemical industry, oil mining, mechanical processing, textile and food industries has attracted widespread attention.

Printing and dyeing wastewater is one of the most difficult industrial wastewater and one of the highly polluting industries. The wastewater has large chroma, high organic content, poor biodegradability, high salt content, large conductivity, large water quality variation range, and large pH value variation, large changes in water temperature and other features. The printing and dyeing wastewater is mainly from the wastewater discharged in the processes of desizing, scouring, drifting, mercerizing, dyeing, finishing and other processes. There are many traditional methods for the treatment of printing and dyeing wastewater, mainly including physical and chemical methods, biochemical methods and biological-physical and chemical composite methods, but the effluent generally cannot be fully meet the discharge standards. With the continuous increase of industrial water demand and the increasingly strict environmental protection laws and regulations, reuse of printing and dyeing wastewater is imperative.

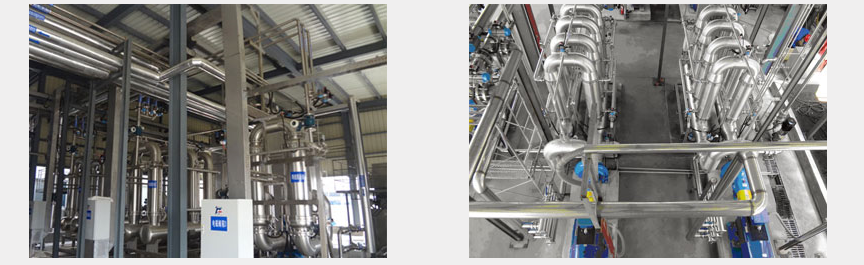

The printing and dyeing desizing wastewater contains a large amount of refractory slurry, which enters the sewage treatment system, and increases the difficulty of biochemical treatment and increases the cost of sewage treatment. Printing and dyeing desizing wastewater contains a relatively high concentration of caustic soda (0.5% to 7%) and a certain amount of refining agent, etc., which has a high recovery value. The ceramic ultrafiltration membrane technology is used to concentrate the printing and dyeing desizing wastewater. The membrane-treated clear liquid is directly reused in the desizing process, in which water and caustic soda can be completely reused to achieve zero discharge of sewage treatment. Jiuwu has achieved very good results by using ceramic ultrafiltration membrane technology to treat desizing wastewater. The refining wastewater of a printing and dyeing factory in Nantong adopts ceramic membrane technology for sewage treatment. The designed treatment capacity of the project is more than 500m3, and the produced water meets the requirements of workshop reuse.

With the rapid development of industry, the types and quantities of wastewater are increasing rapidly, and the pollution of water bodies is becoming more and more extensive and serious, threatening human health and safety. For the protection of the environment, the treatment of industrial wastewater is more important than the treatment of urban sewage.

Ceramic membranes have received more and more attention because of their excellent performance. The importance and promotion of water reuse by industrial end users has created a favorable development environment for ceramic membranes.

Since ceramic membrane filtration has the advantages of high separation efficiency, energy saving, simple equipment and convenient operation, it has great potential for development in the field of wastewater treatment. However, because industrial wastewater often contains substances such as acids, alkalis, and oils, the treatment conditions are more demanding. Therefore, the membranes used to treat wastewater must have better material properties, so as to maintain good separation performance and longer service life under harsh conditions. In view of the complexity of industrial wastewater and the differences in on-site operating conditions, ceramic membrane ultrafiltration technology will also have certain deficiencies in the process of treating oily wastewater. Any single treatment technology may not achieve the desired results. We must pay attention to the research and application of the integrated process of membrane separation technology and other water treatment technologies, take advantage of various technologies, and form a new process for advanced wastewater treatment, thereby continuously enhancing the role of ceramic membrane ultrafiltration technology in the treatment of industrial wastewater.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español