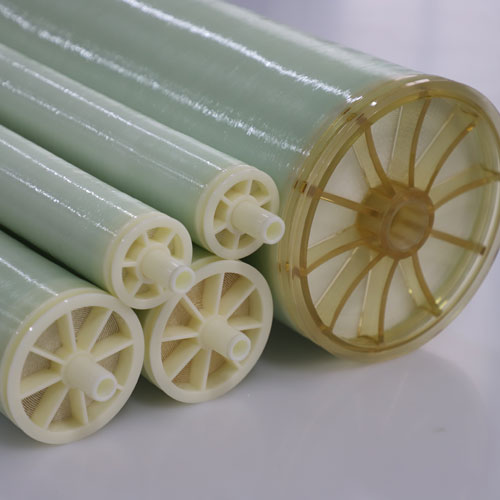

JIUWU HI-TECH has been delivering a full series of spiral membrane products with various molecular weights such as RO, UF, NF, MF through high-stability membranes combined with advanced automated production technology, which are widely used in the chemical industry, pharmaceutical industry, food industry, and water treatment, wastewater reuse.

Spiral wound membrane has features of compact structure, reasonable surface area/volume ratio, anti-pollution, cleaning resistance, and convenient maintenance.

The option of 13-120mil wide range flow channel can meet the needs of various viscosities, which achieves the purpose of reducing energy consumption.

We can provide special custom-made spiral spiral wound membrane, including spiral wound membrane element and spiral wound membrane module with high pressure resistance, acid & alkali resistance, high temperature resistance &solvent resistance for some special applications.

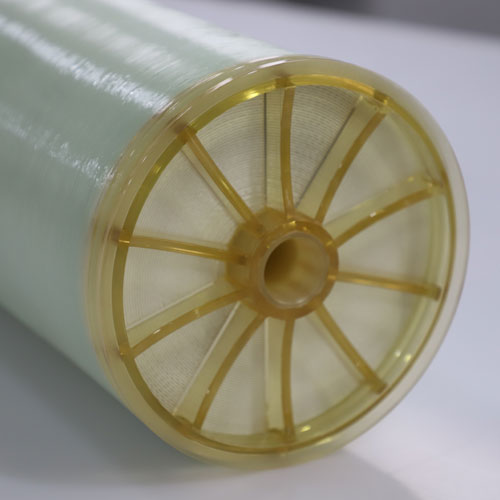

The spiral wound membrane is inserted between the two membrane filaments through a permeate spacer (made of polypropylene or vexar),the three edges of the two membrane filaments are bonded and sealed with epoxy or polyurethane adhesive, and the fourth unbonded edge is fixed on the central tube of the opening.

In this way, two membrane filaments and one permeate spacer form a "membrane bag" with one side opening and three sides sealing.The opening of the "membrane bag" is just opposite the hole of the central tube, and the permeate passing through the membrane can be collected in the central tube.The front side of the membrane, that is, the side through which the feed liquid flows, is lined with a feed-liquid spacer. The feed-liquid spacer and the "membrane bag" are wound into a spiral around the central tube.There is a layer of membrane sleeve outside the membrane roll, which is used to prevent the feed liquid from spreading the roll configuration. The two ends of the membrane are also provided with an anti expansion member (ATP) to protect the membrane from the pressure drop in the flow direction. Then a roll type membrane core is formed.Spiral membrane is wound from a "membrane bag" ,known as "single leaf". At present, most of the commercial membranes adopt a "multi-leaf" structure. Under the membrane area is roughly the same, the flow passage of the permeate of the multi-leaf is shorter than that of the single leaf, which reduces the back pressure loss, increases the flux, and makes the flow of the flow passage more uniform.

In practical applications, one or several spiral wound membrane cores are installed in a circular tubular pressure vessel (membrane shell), and the central tube of the membrane core is sealed in series with the water outlet on the end cap of the membrane shell to form a spiral membrane module .After the pressurized feed liquid enters from the inlet of one end of the membrane shell, it flows through the feed liquid flow channel formed by the feed liquid spacer in the direction parallel to the center tube and flows through the membrane surface, and flows out from the outlet of the other end of the membrane shell, forming a rejection, also called concentration. The permeate that permeates through the membrane passes through the permeate flow channel in the membrane bag along the spiral direction, flows into the central tube and is led out.

Spiral membrane can be used in a wide range of industries. Such as soft drink processing and production in the beverage industry, whey concentration and whey desalination in the dairy industry, ultra-pure water purification for semiconductors in the electronic and microelectronics industry, and separation of fruit juice, beverages, alcohol, sugar, starch, etc. in the food processing industry /Purification, refining/concentration, pigment decolorization, oil-water separation, recovery of valuable materials in manufacturing and electroplating industry, removal of silica gel iron and silica gel in boiler feed water in power industry, classification/concentration of active substances in biological products, municipal administration Water removal hardness/color, RO and RO pretreatment, etc.

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español Contact Us

Contact Us

.jpg)