With the rapid development of industrial economy, water pollution is becoming more and more serious. Industrial wastewater contains a large amount of waste, heavy metals, organic intermediates and other toxic and harmful pollutants, which seriously threatens the safety of water resources.

In April 2015, the State Council released the "the Action Plan for prevention and control of water pollution" which clearly proposed that waste water generated by industries such as papermaking, coking, nitrogen fertilizers, non-ferrous metals, printing and dyeing, agro-food processing, API manufacturing, tanning, pesticides, electroplating, etc.should be carried out special treatment.

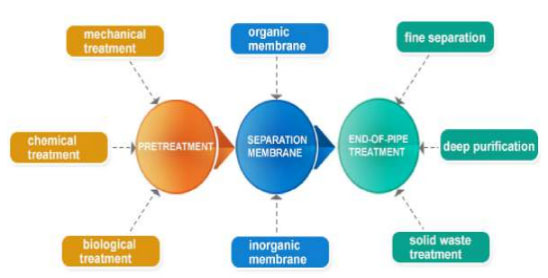

Membrane integration technology has been applied in industrial wastewater treatment fields such as zero liquid discharge of papermaking wastewater, recycling of coking wastewater , printing and dyeing wastewater reuse & recovery, and advanced treatment of electroplating wastewater.

JIUWU HI-TECH adopts multi-membrane integrated technology to develop various characteristics of zero liquid discharge wastewater and waste salt recycling processes for papermaking, printing and dyeing, chemical industry, metallurgy and other industries. The recycling rate of water treated by the membrane process exceeds 95%, and the inorganic salts in the wastewater are further used as by-products in related industries.

JIUWU HI-TECH can provide customized solutions according to customer needs, including thermal process and freezing process.

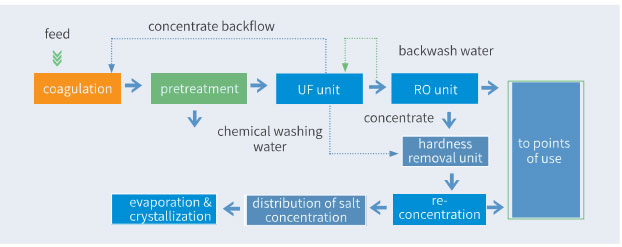

The evaporative crystallization process is used to obtain by-product inorganic salts through pretreatment, membrane concentration, and salt ion blending systems. Some inorganic salts are obtained through acid-base preparation units for acids and bases, which are used in water treatment processes and chemical auxiliary materials preparation.

Fig1. ZLD thermal process

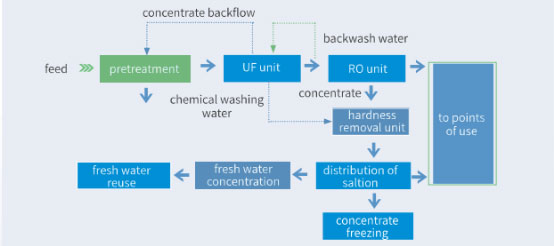

According to the characteristics of some salts, the by-product inorganic salts were obtained by freezing crystallization process.

Fig2. ZLD freezing process

According to the different types of inorganic salts in wastewater from different industries, different treatment processes are adopted to obtain different inorganic salt products.

Through the above process, the operating cost of the system can be controlled at RMB4.00-RMB6.00 per ton of water, and the profit of the product ranges from RMB 2.00-RMB8.00, which can make up part of the operating cost of the wastewater zero liquid discharge system.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español