In order to eliminate the heat of deformation generated during cold rolling of strip steel, steel enterprises need to use emulsions or palm oil for cooling and lubrication. However, the process of rolling steel produces a large amount of oily (emulsion) wastewater, which is not only wasteful, but also causes serious environmental pollution. Therefore, from the point of view of saving resources and energy as well as protecting the environment, these wastewater should be treated and recycled or partially discharged. However, the concentrated oily wastewater is a kind of high concentration and hard to degrade wastewater, which is difficult to be treated by physical and chemical methods such as air flotation, adsorption, biochemical and chemical methods. Ultrafiltration membrane technology has the advantages of strong acid and alkali resistance, high mechanical strength, uniform pore size distribution, good temperature resistance, long service life, etc., which has attracted widespread attention at home and abroad, and has been applied in many fields. Therefore, in the treatment of cold rolling waste water, we first consider using in organic ultrafiltration ceramic membrane for pretreatment, followed by advanced technology, mature and reliable microbial technology for treatment. At the same time, it adopts cross-flow operation, which has the advantages of large membrane flux, anti-pollution and long-term operation without clogging, etc. The thick oil wastewater can directly enter the ultrafiltration system without complicated pretreatment, which can solve the problems that are difficult to be solved by conventional treatment technology.

The waste emulsion is sent to paper belt filter by lifting pump to remove the coarse scum and part of iron powder in the wastewater, to ensure that the wastewater entering the circulation box does not contain solid particles larger than 0.5 mm and the solid content does not exceed 1%. The wastewater is filtered through membrane equipment and the filtrate is discharged to the next process for further treatment. The oil slick on the circulation tank overflows to the oil separation tank periodically, and after separation, it is sent to the waste oil storage tank and then shipped out. The thick oily wastewater in the circulation tank is pumped to the oil separation tank periodically, and the oil and water are separated after heating and acid addition. The membrane system is also equipped with a cleaning system, which cleans the membrane equipment regularly to restore the permeation flux of the membrane equipment, and the waste cleaning liquid is discharged to the regulating tank.

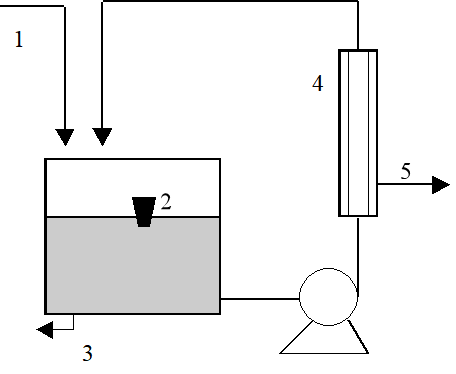

Flow chart of ceramic membrane treatment of cold rolling emulsion wastewater

1: Waste emulsion

2: Oil scraper

3: Sludge

4: Membrane module

5: Permeate

Technical Features

The oil retention rate is high, and the oil content in the effluent is less than 10ppm, which meets the requirements of environmental protection.

The membrane flux is higher than the organic membrane, and the flux is 50-150l/(m2-h).

Long service life of membrane pipe, low investment of equipment, 8-10 years of operation life and three years of quality guarantee.

The long cycle of membrane operation, short cleaning time, and the use of higher concentration and higher temperature of acid and alkali solutions that organic membranes cannot bear make the cleaning flux recovery effect good and stable, with low price and low dosage, which can be used repeatedly without secondary pollution.

The treatment process is simple, easy to achieve automatic control, operating energy consumption is much lower than organic membrane equipment.

All the equipment is made of stainless steel, less wearing parts, simple equipment maintenance, low maintenance costs.

Case presentations

Size of steel plant: 1.3 million tons of cold-rolled thin plate production line per year.

Cold rolling emulsion wastewater volume: 20 tons per hour

Scale of inorganic ceramic membrane emulsion equipment: 20 sets of ultra-filtration host units

Total power of equipment: 240KW

Water quality index: oil content less than 10ppm, COD about 3000ppm, SS less than 30mg/L.

Membrane cleaning: the choice of chemical cleaning agents and cleaning methods depending on the determination of the raw liquid system through experiments. Experiments and related industrial applications confirm the contamination of rolling emulsion on the membrane, usually using alkali, acid alternate cleaning to restore the membrane flux, which can remove oil pollution with alkali, acid can remove metal salt pollution.

Ceramic membrane treatment technology is also used in the treatment of emulsion wastewater from copper/aluminum rolling, degreasing cleaning solution treatment for coating lines, grease refining wastewater treatment, degreasing cleaning solution treatment for galvanizing lines, oily wastewater treatment for the machinery processing industry, and wastewater treatment for money printing.

Conclusion: Because membrane filtration technology has the advantages of high separation efficiency, energy saving, simple equipment, convenient operation, etc., it has great potential for development in the field of wastewater treatment. However, industrial wastewater often contains acid, alkali, oil and other substances, and the treatment conditions are quite harsh, therefore, the membrane used to treat wastewater must have better material properties, so as to maintain good separation performance and long service life under harsh conditions. In view of the complexity of industrial wastewater and the differences in field operation, there will be certain shortcomings of ceramic membrane ultrafiltration technology in the treatment of cold-rolled oily wastewater, any single treatment technology may not achieve the desired results. It is necessary to pay attention to the integrated process research and application of membrane separation technology and other water treatment technologies, give full play to the advantages of various technologies, and form a new process for deep treatment of wastewater, so as to continuously improve the role of ceramic membrane ultrafiltration technology in the treatment of oily wastewater.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español