In the plant extraction industry, efficient and environmentally friendly separation technology is the core issue driving industrial upgrading. Currently, the limitations of traditional processes have led many companies into a predicament of high costs, low efficiency, and significant pollution.

Jiuwu Hi-tech, leveraging its independently developed organic tubular membrane technology, has partnered with a pharmaceutical company to break through traditional production bottlenecks with innovative organic tubular membrane technology, bringing revolutionary breakthroughs to the field of plant extraction. This technology relies on advanced organic tubular membrane separation principles to precisely separate and extract target components, avoiding the loss and residual impurities caused by multiple extractions and distillations in traditional processes.

The contradictions in improving quality and efficiency, as well as green manufacturing in traditional plant extraction processes, are becoming increasingly prominent. Under the dual pressure of industrial production demands and refined quality control, the existing process systems expose three major core issues in key links, becoming the main bottlenecks restricting industrial upgrading.

The existing filtration systems lack sufficient filtration precision, leading to the loss of target components and generally low process yield. They also strongly depend on filter aids/flocculants which introduce external impurities, posing environmental risks.

Pressure filtration units require manual unloading (3-5 times per shift), filter cloth cleaning (taking 40-60 minutes each time), and other operations, resulting in effective operational time being less than 6 hours per shift, and labor costs exceeding 25% of total process costs.

Plate-frame filter press units cover an area of 8-12 square meters per unit, and auxiliary equipment like storage tanks are dispersed, making space utilization in extraction workshops over 35% for equipment.

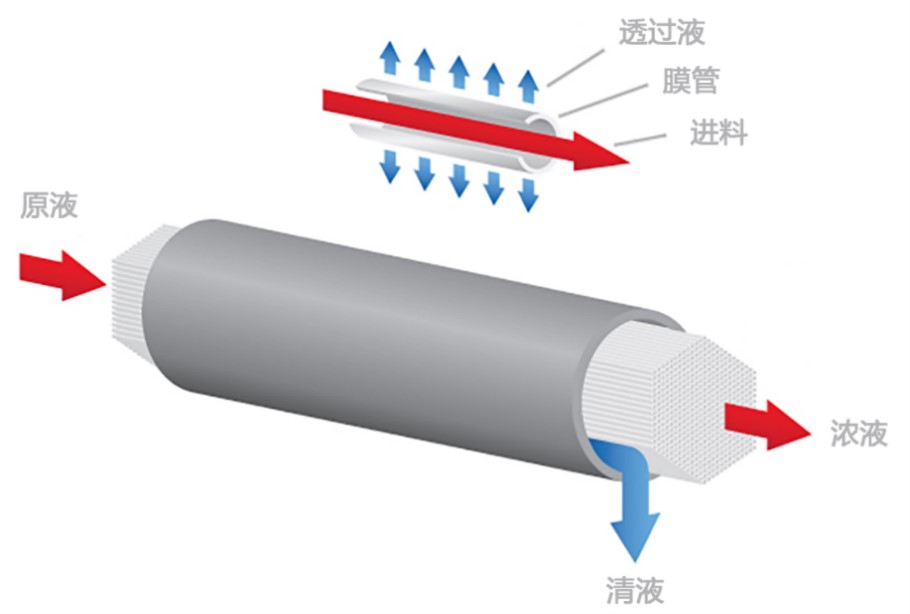

In this project, the process employs a full-process combination of "water extraction + tubular ultrafiltration + nanofiltration + reverse osmosis," ultimately stabilizing the purity of herbal extraction to over 95%. Among them, the organic tubular membrane, with precise filtration precision, accurately separates macromolecular target extracts and small molecular substances. Meanwhile, the tubular membrane system can achieve high multiples of concentration treatment of feed liquids, enhancing the efficiency of the subsequent drying process and saving energy.

Compared to the old process, the concentration efficiency has increased by about 7 times, and the production cycle has been significantly shortened. In terms of energy saving and emission reduction, water consumption in the new process has been reduced by 45%, saving 36,000 tons of water annually; operating costs have decreased by 30%, saving more than 5 million yuan annually, alleviating the economic burden on enterprises and promoting green manufacturing in the industry.

The organic tubular membrane adopts an asymmetric porous structure, with filtration precision selectable from 10 to 100 nanometers, effectively retaining macromolecular impurities while allowing the efficient passage of target small molecular components. Taking traditional Chinese medicine extraction as an example, this technology can increase the recovery rate of active ingredients by more than 20% and remove impurities by up to 90%.

Using membrane cores with 6-12mm wide flow channels can enhance concentration multiples and significantly reduce membrane clogging risks, while reducing wash water consumption, and saving operating costs with the help of an automated control system, truly achieving a win-win situation for green production and economic efficiency.

The inner wall of the organic tubular membrane is smooth, and the fluid forms a self-cleaning effect in high-speed flow, significantly reducing membrane pollution risks. Even when facing high-viscosity, suspended plant extracts, it can still maintain long-term stable operation, reducing cleaning frequency by 50% compared to traditional membrane technology.

The tubular membrane system adopts a modular design with a compact layout, covering only 1/3 to 1/2 of the area of traditional processes, reducing civil construction costs.

The successful application of Jiuwu Hi-tech's organic tubular membrane technology not only solves the development dilemma of "high cost, low efficiency, and heavy pollution" for individual enterprises, but also demonstrates a clear path of "technology-driven efficiency revolution" for the plant extraction industry.

In the future, with the continuous iteration of membrane technology and the continuous expansion of industry application scenarios, the plant extraction industry may undergo a full industry chain transformation from "extensive processing" to "precision manufacturing," and Jiuwu Hi-tech's innovative practice is a vivid footnote to this transformation.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español