Membrane is a material with selective separation function. The process of using the selective separation of the membrane to realize the separation, purification and concentration of different components of the feed liquid is called membrane separation. It is different from traditional filtration in that the membrane can be separated in the molecular range, and this process is a physical process that does not require phase changes and additives. The pore size of the membrane is generally micron. According to the difference of its pore size (or called the molecular weight cut-off), the membrane can be divided into microfiltration membrane, ultrafiltration membrane, nanofiltration membrane and reverse osmosis membrane. According to the different materials, it can be divided into Inorganic membranes and organic membranes, inorganic membranes are mainly ceramic membranes and metal membranes, which have low filtration accuracy and low selectivity. Organic membrane is made of polymer materials, such as cellulose acetate, aromatic polyamide, polyethersulfone, and polyfluoropolymer. The separation and retention performance of various membranes in the cross-flow membrane process are distinguished by the pore size and molecular weight of the membrane.

Compared with traditional separation technology, membrane separation technology has the following characteristics:

① Membrane separation is an efficient separation process that can separate thousands or even hundreds of substances with relative molecular weight.

② The membrane separation process basically has no “phase” change, low energy consumption, and high energy conversion rate.

③ The membrane separation process can be carried out at room temperature and is suitable for the separation, classification and concentration of heat-sensitive materials such as juice, enzymes, drugs, as well as water and wastewater treatment and purification.

④ The membrane separation equipment has few moving parts, simple structure, convenient operation, control and maintenance.

⑤ The membrane separation efficiency is high, the equipment is small in size, the area occupied is small, and the application range is wide.

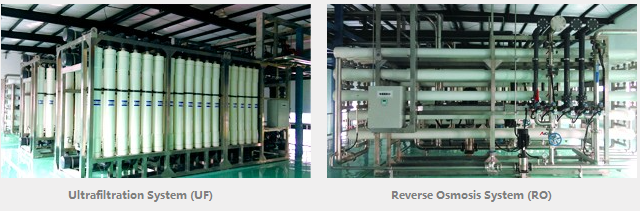

As one of my country's traditional livelihood industries, the printing and dyeing industry has always been the lifeblood of the development of the national economy. However, the drainage volume of the printing and dyeing industry accounts for more than 30% of the total drainage volume of industrial wastewater. Therefore, improving the advanced treatment and recycling technology of printing and dyeing wastewater is of great significance to alleviate the pressure on my country's water resources. In recent years, the double-membrane method (ultrafiltration + reverse osmosis) as the main printing and dyeing wastewater reuse technology has been widely used. Jiuwu Hi-Tech uses the ultrafiltration and reverse osmosis integrated membrane process for advanced textile dyeing wastewater treatment to realize the reuse and zero discharge of printing and dyeing wastewater.

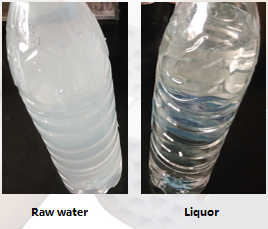

Effect after treatment:

| Test item | Raw water | Effluent |

| PH | 6-8 | |

| Conductivity | ≤3000 | <50 |

| Total hardness | ≤80 | |

| Turbidity | ≤30 | ≤0.1 |

| Solid content | ≤5 |

Figure: index of raw water and effluent

Jiuwu Hi-Tech uses integrated technologies such as resin softening, membrane integration technology, and freezing crystallization to achieve "near zero discharge" of wastewater, and the salt obtained is glauber's salt, which realizes the resource utilization of wastewater and waste salt. Aiming at the organic-rich concentrated brine produced by a printing and dyeing textile company in Jiangsu, the wastewater was concentrated 70-80 times through pretreatment, membrane integration process and coupled frozen crystallization, and then high-purity sodium sulfate products (up to the first-class product in Class II ) and industrial water that meets the requirements of production were obtained, achieving the reduction and resource utilization of concentrated brine. The project relieves the pressure on water for enterprises and provides ideas for the reduction of concentrated brine and the comprehensive utilization of resources in the printing and dyeing textile industry.

Facing the increasing shortage of resources and the deteriorating environment, more and more enterprises realize the importance of following the principles of reduction, reuse, and recycling in the industrial production process, and begin to seek the recycling of wastewater and salt in the enterprise, and finally realized "zero discharge" of pollutants in the enterprise. However, if most companies want to truly achieve zero discharge, in addition to investing a large amount of environmental protection funds themselves, they must also have the support of external advanced "zero discharge" technologies. Based on this, Jiuwu Hi-Tech has invested a lot of manpower and material resources to develop a variety of advanced zero-discharge coupling technologies for advanced industrial wastewater treatment. Through technological innovation and technological iteration, it serves relevant enterprises and helps enterprises reduce the emissions of three wastes.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español