As the first grand event for the water treatment industry in South China during the spring season, the 2025 Guangdong Water Expo will be held from March 5-7 at Guangzhou | Poly World Trade Center Expo. The event is organized by the China Membrane Industry Association, the China Instrument and Control Society, and other units. With an exhibition area of 36,000 square meters and over 800 quality exhibitors covering municipal, industrial, and domestic three major fields, more than 20,000 products will be showcased. Various new technologies, new products, and new activities will debut successively, making it a high-quality water treatment business platform that integrates buyer meetings, business negotiations, new product releases, and high-level forums.

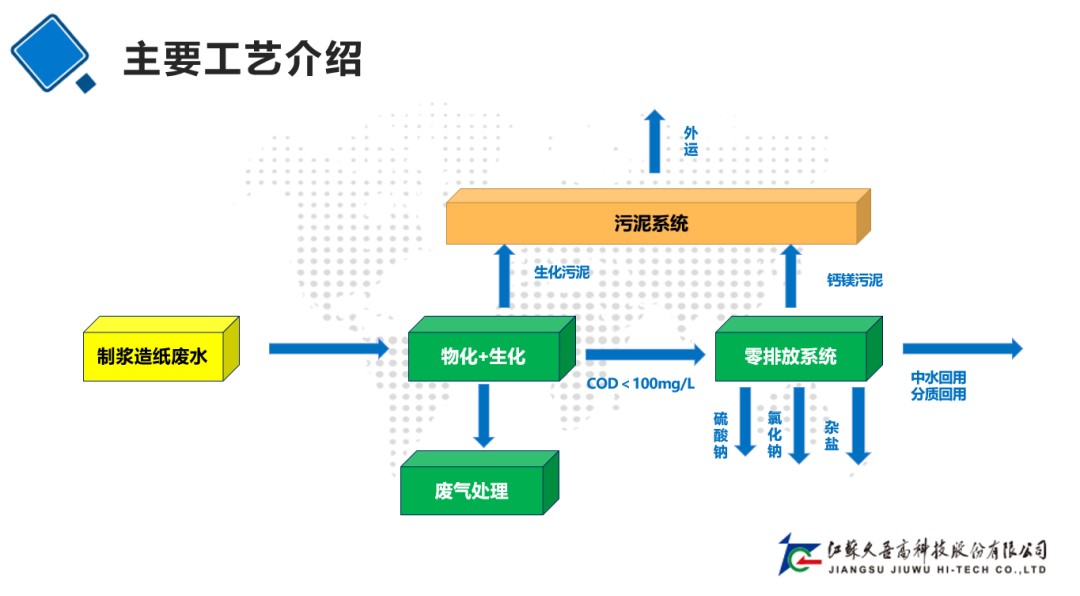

As a leading enterprise in the ceramic membrane field of China's membrane industry, Jiuwu Hi-tech was invited to participate in this exhibition. R&D engineer Zhang Chun gave a keynote speech on "Application of Membrane Integration Technology in Pulp and Paper Wastewater Recovery and Resource Utilization," introducing Jiuwu Hi-tech's processes and related cases in the industrial wastewater field.

In recent years, Jiuwu Hi-tech has accumulated rich design and engineering application experience in zero discharge of paper-making wastewater, metallurgical wastewater, and printing and dyeing wastewater by relying on mature and complete membrane integration technology. Especially in the field of zero wastewater discharge technology, the company has applied for 33 Chinese patents, including 7 granted invention patents, establishing a core patent protection cluster that includes the development of special membrane materials, the resource utilization processes, and application equipment key technologies for waste salt and high-concentration salty water.

Traditional zero discharge has drawbacks such as large project investment, high operating costs, and the production of a large amount of waste salt. The high cost of third-party governance for waste salt makes it unaffordable for enterprises and governments, and it may even cause serious waste salt pollution.

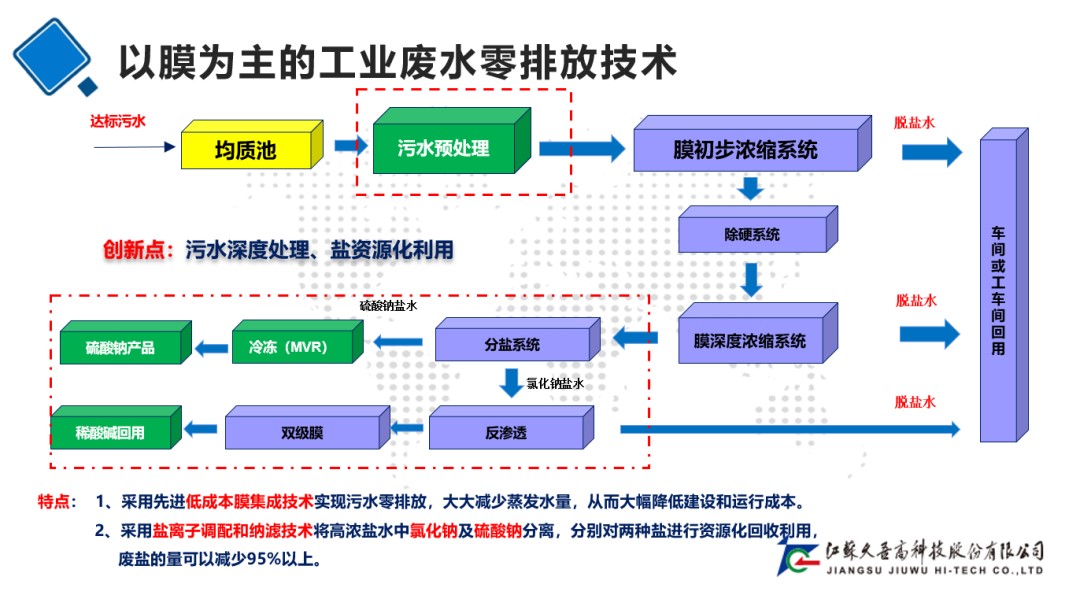

Compared with traditional wastewater zero discharge, Jiuwu Hi-tech's membrane-based industrial wastewater zero discharge technology adopts advanced low-cost membrane integration technology to achieve zero wastewater discharge, greatly reducing evaporation water volume and significantly lowering construction and operation costs. The technology separates sodium chloride and sodium sulfate from high-concentration salty water using salt ion adjustment and nanofiltration technology, respectively recycling and utilizing these two salts, reducing the amount of waste salt by more than 95%.

Using hardness removal ponds and sodium ion exchange technology, the hardness of the wastewater can be controlled below 5 mg/L;

Precision dosing system automatically adjusts based on water volume and quality;

Coupled with the membrane, SDI<5.

Ultrafiltration unit: Optimizes the operating parameters of the ultrafiltration, using a reliable operation mode to ensure the stability of the ultrafiltration membrane system and extend the life of the ultrafiltration membrane.

Adopts a two-stage reverse osmosis process to improve wastewater concentration multiples;

Reverse osmosis concentrated water directly enters the deep softening system;

Uses a mature reverse osmosis process with material separation control and maintenance approach + high-efficiency reverse osmosis antiscalant to ensure that the reverse osmosis unit can run stably under high hardness conditions.

Uses a patented process combining salt separation and nanofiltration; the freshwater COD content of the salt separation system is low and can be re-concentrated in subsequent processes;

The concentrated water of the salt separation system has a total salt content of over 100,000 mg/L (10%), reducing the treatment volume of the evaporation crystallization system;

After treatment by the salt separation system, the sulfate: chloride ratio in concentrated water is 4.5:1, and in freshwater, the sulfate: chloride ratio is 1:10.

High-pressure reverse osmosis: Technically mature, spool membrane has moderate anti-pollution capabilities, pressure-driven, not highly concentrated (about 6%), resulting in significant concentrate volume and high subsequent evaporation costs.

Tubular reverse osmosis: Strong anti-fouling capabilities, disc-type structure, pressure-driven, pressures up to 90-120 bar, requires high piping material standards, has operational safety risks, and concentrates about 10%, with high investment costs.

Electrodialysis: Driven by an electric field, operates at ambient pressure, high safety, high concentration capability reaching 12%-15%, low operating energy consumption, flat panel membrane structure, strong anti-fouling capability, allows separation of non-conductive organics and salts, ensuring salt quality.

Membrane and membrane integration technology-based wastewater treatment solutions will be one of the mainstreams for future wastewater treatment and emission reduction, injecting technological momentum to achieve "dual carbon" goals. In the future, Jiuwu Hi-tech will continue to focus on membrane technology research and development, accelerating the promotion of green transformation in the industrial water treatment sector, helping China's water treatment industry to reach higher levels.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español