Nanofiltration membrane technology, as an efficient separation and concentration technology, is widely used in various fields. Among them, acid and alkali recovery is one important application. This article will introduce the application and advantages of nanofiltration membrane technology in acid and alkali recovery.

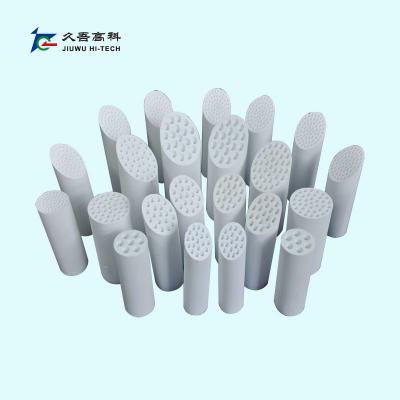

Nanofiltration membranes are special semi-permeable membranes with pore sizes ranging from a few nanometers to tens of nanometers. They can retain organic molecules with molecular weights ranging from a few hundred to a few thousand, while allowing small molecules to pass through. Nanofiltration membrane technology utilizes this feature to separate ions, molecules, and colloids from a solution under pressure, achieving separation and concentration of the solution.

Acid and alkali recovery is one of the important applications of nanofiltration membrane technology. In fields such as chemical, pharmaceutical, food, and environmental protection, large amounts of acid and alkali solutions are used, which often contain a large number of impurities after use and need treatment. Nanofiltration membrane technology can effectively retain impurities in acid and alkali solutions while concentrating the acid and alkali solutions that need to be recovered, achieving resource recovery and reuse.

For example, in chemical production, a large amount of sulfuric acid is used for catalytic reactions, and the sulfuric acid solution after the reaction contains a large number of impurities. Using nanofiltration membrane technology, impurities can be retained while the sulfuric acid solution is concentrated for recycling. This not only reduces the generation of waste liquid but also lowers production costs.

Nanofiltration membrane technology has the following advantages in acid and alkali recovery:

High separation efficiency: The small pore size range of nanofiltration membranes can effectively retain larger molecular weight impurities while allowing the acids and alkalis that need to be recovered to pass through. This greatly improves the separation efficiency of acid and alkali recovery.

Low energy consumption: Nanofiltration membrane technology does not require heating or cooling during use, resulting in low energy consumption. Additionally, due to its high separation efficiency, the overall energy consumption in the recovery process is low.

Environmentally friendly: Nanofiltration membrane technology is a non-chemical separation method that does not require the use of chemical reagents. This not only reduces the generation of waste liquid but also benefits environmental protection.

Easy operation: The operation of nanofiltration membrane technology is relatively simple and can be automated for continuous operation. This greatly reduces labor costs and improves production efficiency.

Wide application range: Nanofiltration membrane technology is suitable for the recovery of various types of acid and alkali solutions and is not limited by the chemical properties and temperature of the solutions. This makes it widely applicable in fields such as chemical, pharmaceutical, food, and environmental protection.

Nanofiltration membrane technology has the advantages of high efficiency, energy saving, environmental protection, easy operation, and a wide range of applications in acid and alkali recovery. With continuous development and improvement, its application in acid and alkali recovery will become increasingly extensive, making greater contributions to resource recycling and environmental protection.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español