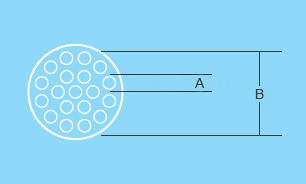

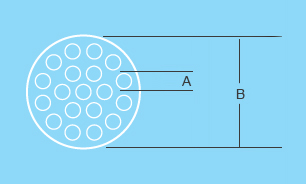

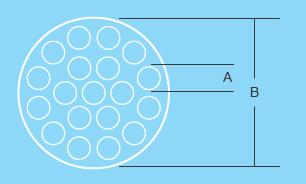

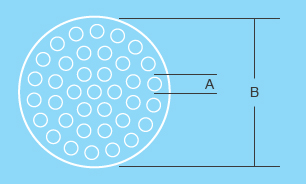

Ceramic microfiltration membrane is a type of physical filter element where a contaminated fluid is passed through a special pore-sized membrane to separate microorganisms and suspended particles from process liquid. The most common application of ceramic microfiltration membrane is clarification, or removal of suspended solids to produce a clear liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and

reverse osmosis membrane technology to provide a product stream which is free of undesired contaminants. Examples include clarification of whole cell broths; purification processes in which macromolecules must be separated from other large molecules, enzymes or cell debris; clarification of dextrose and highly colored fruit juices, wine and beer, during which

fruit juice membrane and

beer membrane filtration will be used

; whey de-fatting and casein removal. Ceramic microfiltration membrane systems operate at relatively low pressures and come in a variety of configurations. They are characterized by pore size, ranging from 0.05 micron to 1 micron.

JIUWU company offers a large choice of ceramic microfiltration membranes with different geometries and cut-offs to meet your process requirements in viscosity, molecule size, impurity profile, purity and yield target, etc. as well as cleaning and sanitization procedures.

MF ceramic membrane usually serves as a pre-treatment for other separation processes such as ultrafiltration, and a post-treatment for granular media filtration. Learn more

micro filtration technology here!

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808