Degreasing process is a necessary step before any other processing in mechanical industry, in the steel industry and generally speaking in the transformation of raw materials.

Degreasing treatment is performed with aid of an aqueous solution containing detergents.

The detergents emulsify oil present on the material to be treated; for this reason, oil concentration tends to increase in degreasing baths until the need for renewal and/or replacement, to avoid loss of efficacy.

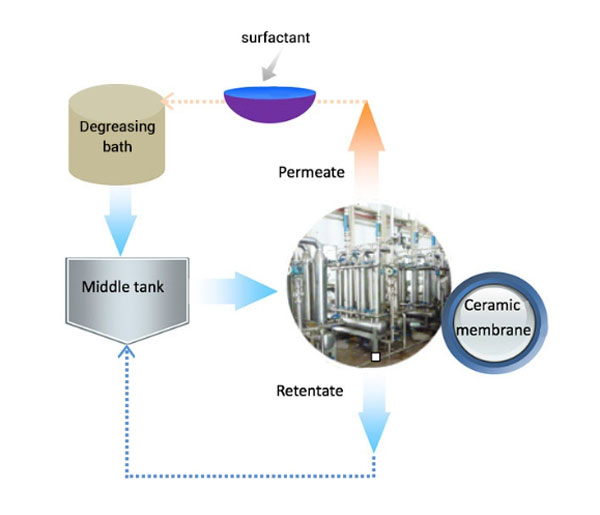

Using ceramic membrane technology, there has two fluids, one is permeated which is constituted by water and detergents present in the original bath, the other is concentrate which contains oils and suspended solids and that is back to oil removal tank. After ceramic membrane treatment, the concentration of oil in the degreasing tank can be maintained at a low and very stable concentration range, the quality of the cleaned steel plate is uniform. The emulsion oil in the waste liquid is subjected to demulsification to reduce the amount of surfactant used in the cleaning solution.

Separation principle

Selecting the appropriate ceramic membrane filtration precision, by utilizing the characteristics that oil molecules and water molecules differ by tens of times in size and hydrophilic membrane surface properties of ceramic membrane, oil molecules can be effectively rejected, and water, degreasing bath, and surfactant small molecules can be recycled through the membrane surface. The degreasing bath is concentrated by the ceramic membrane system, and the volume of the discharged waste liquid is greatly reduced.

Technical benefits

1. Oil is removed and decreasing baths can be recycled ;

2. Costs of adding chemicals are significantly reduced;

3. The usage of surfactant is greatly reduced because of SS removal ;

4. Regeneration period is prolonged to 6 months or more ;

5. Subsequent wastewater treatment cost is decreased ;

6. Longer service life, lower operating pressure and lower energy consumption;

7. Simple, compact, fully PLC control

8. Ceramic membrane has excellent chemical resistance, high-temperature resistance and high separation precision

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español