Enzymes are products extracted and purified from fermentation broth or natural products. They are highly efficient, specific, and active under appropriate conditions. The extraction aqueous solution contains a small number of enzymes but a large number of suspended solids, high molecular, and low molecular impurities. The concentration and purification methods currently used include precipitation, adsorption, chromatography, freezing, vacuum concentration, and ultrafiltration centrifugation, etc. But the separation and purification effects and costs are relatively high. While the membrane separation method uses the pressure difference between the two sides of the membrane to allow water and small molecular substances to pass through the membrane, while macromolecular substances such as enzymes are trapped in the membrane by the membrane to achieve concentration and purification of enzymes.

At present, UF technology is used globally to concentrate and refine the crude enzyme solution, and large-scale production has been carried out in the United States, Japan, and Denmark. The enzyme preparation industry is a knowledge-intensive high-tech industry and an important part of bioengineering. It is reported that about 3000 kinds of enzymes are found worldwide, and there are about 60 kinds of enzymes produced in industry, but only more than 20 kinds are industrialized and mass-produced. According to statistics from relevant agencies, the world's enzyme preparation market is increasing year by year at an average annual rate of 11%. Therefore, the development prospect of the enzyme preparation industry is quite broad. Enzyme preparations are widely used in food processing, medicine, agriculture, and chemical industries.

The production of enzyme preparations by fermentation often requires five steps of culture, namely, cell disruption, extraction, separation and purification, and concentration and purification. The key to the quality of enzyme preparations lies in the quality of cultured enzymes, the removal of impurities, and the recovery of enzymes during extraction and purification. The molecular weight of enzyme preparations is generally between 10,000 and 200,000 Daltons, which is just between the application range of microfiltration and ultrafiltration technology. First ultrafiltration membranes are adopted to separate macromolecular substances such as broken cells and culture media from enzyme preparations. Then ultrafiltration or nanofiltration membranes are adopted to concentrate and purify the purified enzyme preparations. Utilizing the good benefits of the membrane at various temperatures, it can still achieve high-efficiency removal of impurities at room temperature or low temperature, which solves the effect of temperature on enzyme preparations and the high energy consumption caused by traditional evaporation and concentration. At the same time, small molecule impurities and most of the salt is removed to improve the purity of the product.

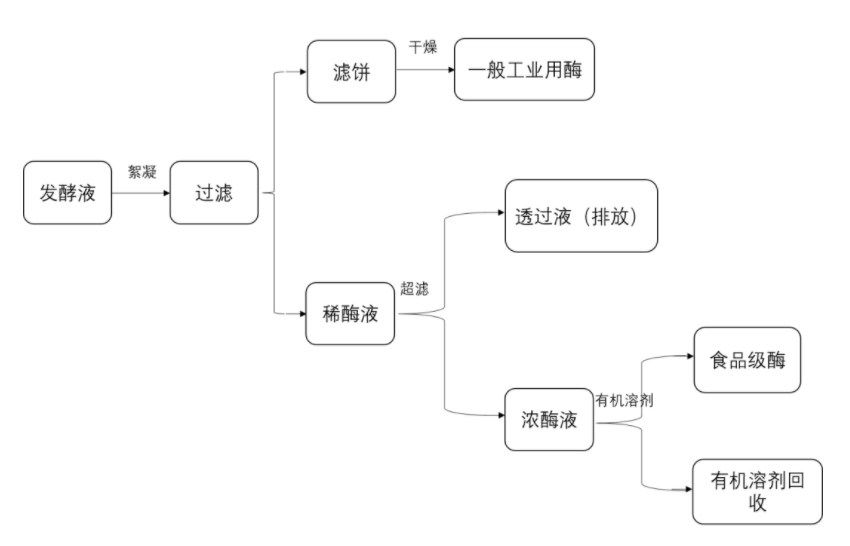

The following figure is the process flow of membrane separation technology applied in the production of enzyme preparations:

The membrane separation technology used in the production of enzyme preparations has the following advantages:

a. Concentration and purification at room temperature reduces the influence of temperature on the activity of enzyme preparations, and the separated products have good purity, high quality, and yield.

b. Compared with vacuum evaporation, ultrafiltration has lower energy consumption, and the energy consumption ratio of the two is 1:8.

c. Compared with salting-out precipitation and solvent extraction methods, inorganic salts and organic solvents can be omitted, such as iron sulfate, magnesium sulfate, ethanol, acetone, and other additives, which not only reduces costs, but also reduces environmental pollution, and is simple to operate.

d. It can be regenerated and cleaned repeatedly and has a long service life;

e. The membrane specifications are designed according to the nature of the material, which can meet the processing of high viscosity and high solid content materials.

d. The automatic PLC design can be cleaned and discharged online, reducing labor intensity, and achieving clean production.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español