Standard discharge, reclaimed water reuse and zero effluent discharge

1. As for paper mill wastewater treatment, pulping wastewater is the most difficult wastewater to be treated in the papermaking industry. The organic pollutants and inorganic salts are high in content, complex in composition, high in hardness, high in costs. The technical staff of JIUWU work with experts from the Institute of Membrane Science and Technology of Nanjing Tech University and develop successfully membrane technology as the core of zero effluent discharge process or zld (zero liquid discharge).Application background

Core advantage of process package

Case

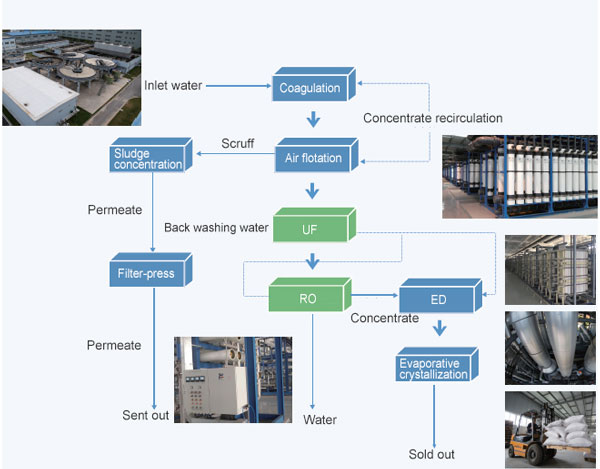

Jiangsu Jiuwu Hitech Co., Ltd has done the largest zero liquid discharge project in paper pulp industry. The project is located in Japanese Oji Paper Co., Ltd. (OJI PAPER) in China, the scale of 40000m3/day of papermaking, pulp wastewater. Main processes include ozone-coupled biofilter (removing COD), the integrated membrane system of uf technology and reverse osmosis, electrodialysis (EDR) concentration system, MVR evaporation crystallization system. Through above-mentioned advanced processing system, the realization of wastewater recycling and zero liquid discharge. The clean water is supplied to the power plant desalination system and the production water system, waste salt is supplied to the Transportation Bureau to do snowmelt agent and chemical raw materials. The project which is the world's largest zero liquid discharge project in paper pulp industry has been stably operating for more than 3 years.Process of Paper Industry Wastewater Treatment

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español