The 17th Shanghai International Water Expo 2025 will grandly open from June 4th to 6th at the National Convention and Exhibition Center (Hongqiao). As a leading enterprise in the field of membrane separation technology in China, Jiuwu Hi-Tech will showcase its full range of membrane product matrices. During the exhibition, we will showcase the strong strength and innovative style of Chinese membrane technology enterprises in all aspects through innovative technology exhibitions, in-depth analysis of application cases, and other forms.

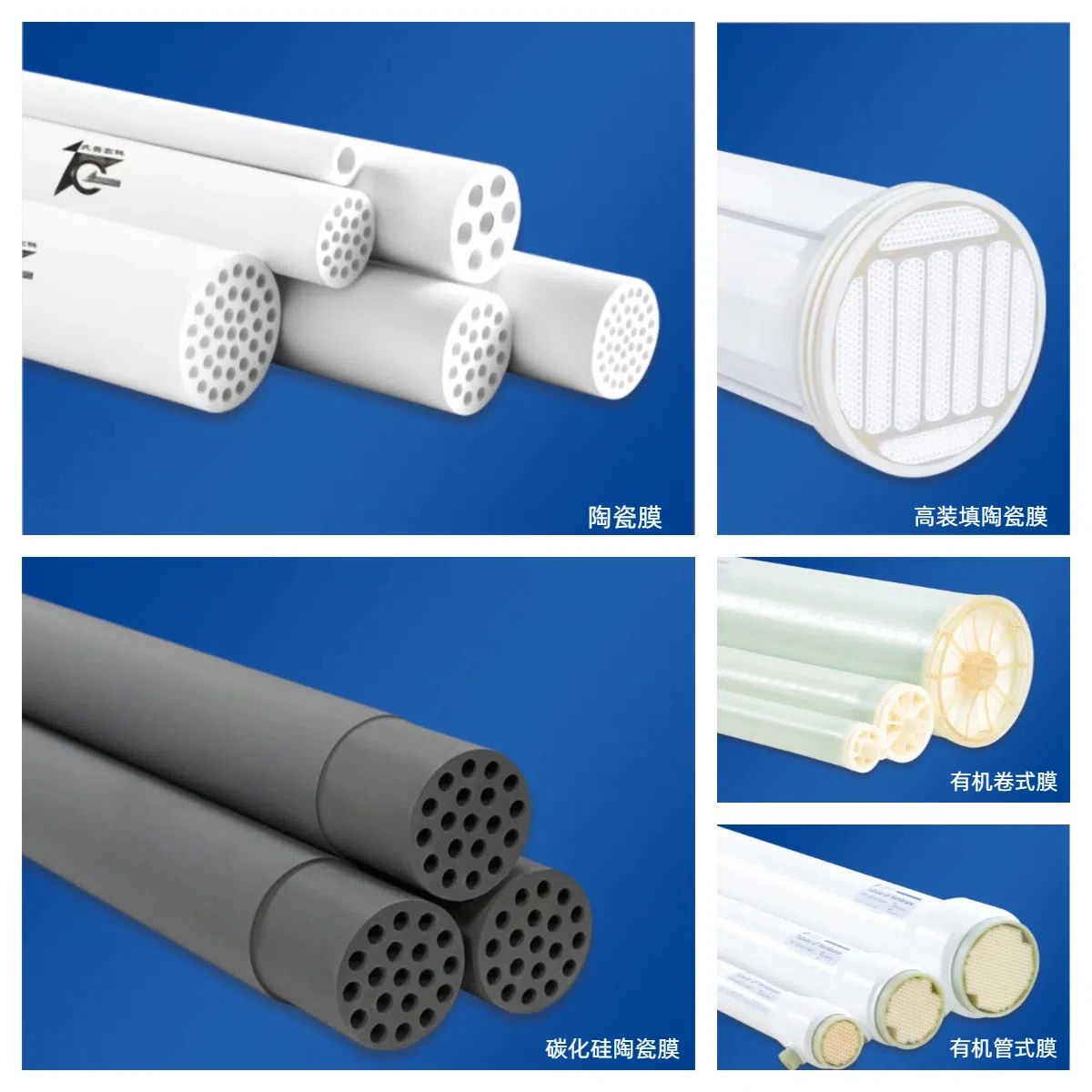

All flagship products from ceramic film to organic film are now available

Jiuwu Hi-Tech developed and produced China's first independent ceramic membrane product in 1997, successfully breaking the foreign technology monopoly and currently ranking first in the domestic market share. This exhibition is not only a concrete presentation of the company's technological accumulation, but also outlines the infinite possibilities of membrane separation technology in industrial efficiency improvement, water treatment, new energy development and other fields. Ceramic Membrane Series: At this exhibition, we will showcase tubular ceramic membranes, high loading ceramic membranes, and silicon carbide ceramic membranes. Jiuwu ceramic film has advantages such as pollution resistance, high strength, and long life. This time, it will showcase its cutting-edge application cases in industrial efficiency improvement, high-end water treatment, and new energy development. Organic Membrane Series: Based on nearly 30 years of fluid separation experience, Jiuwu High tech Organic Membrane combines membranes with customer business needs, leveraging the characteristics of different membranes and applying them to different customer scenarios. The organic membrane product line covers categories such as roll up membranes, hollow fiber membranes, and organic tubular membranes. It uses high-performance materials such as PVDF and PES, combined with unique process design, to meet the needs of different scenarios. Reverse osmosis membrane element: made of aromatic polyamide material, mainly used in pure water, ultrapure water manufacturing, reclaimed water reuse, seawater desalination, separation and concentration of feed solution and other fields. Nanofiltration membrane element: made of poly (piperazine amide) material, mainly used in softened water treatment, chemical wastewater treatment, separation and concentration of precious metal recycling materials, dye decolorization, heavy metal removal and other fields. Ultrafiltration membrane element: made of polyether sulfone/polysulfone polyvinylidene fluoride/regenerated cellulose material, mainly used in sugar decolorization, juice clarification, dye purification/protein concentration separation, oil-water separation and other fields. Microfiltration membrane element: made of polyvinylidene fluoride/polyether sulfone material, mainly used for clarification of fermentation broth, removal of suspended solids, and clarification of biochemical dissolved products.

Deep decoding of technological highlights, foreseeing the future of membrane separation

At the exhibition site, we will unveil how membrane technology is reshaping the industry landscape through intuitive exhibition areas and innovative technology exhibition areas. The innovative technology exhibition area will visually present the breakthrough of the entire chain from membrane material research and development, membrane component design to system integration, showcasing the company's achievements in the fields of ceramic membranes and organic membranes. Application case analysis: In popular fields such as environmental protection and zero wastewater discharge, this article deeply interprets how membrane technology can help customers reduce costs, increase efficiency, and achieve low-carbon transformation.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español