Background

Light olefins, especially ethylene and propylene, play a pivotal role in modern petroleum and chemical industry as basic organic chemical raw materials.

The technology of producing olefins from coal through methanol (MTO/DMTO) can replace naphtha cracking to produce low-carbon olefins, saving crude oil and naphtha resources, and alleviating the shortage of petroleum and olefin resources.

MTO/DMTO is a chemical technology that uses methanol as raw material to produce light olefins through methanol dehydration in a reactor.

During the MTO/DMTO reaction process, the products are mainly light olefins, and large amounts of by-products such as water, mixed alkanes, olefins, aromatic hydrocarbons and yellow-brown oily liquids are also generated.

When water is used as an absorbent to absorb light hydrocarbons such as methanol, dimethyl ether and other heavy hydrocarbons in the product gas, the light hydrocarbons such as methanol and dimethyl ether are stripped out and returned to the reactor to participate in the reaction; while some heavy hydrocarbons in the water, such as the emulsified paraffin and yellow-brown oily liquid will be continuously enriched in the circulating water. After heat exchange through heat exchanger, the water temperature will drop, and the emulsified oil in the water will be adsorbed in the heat exchanger, resulting in a decrease in the heat exchange effect, even blocking the heat exchanger seriously affects the stable operation of the system

During the MTO/MTP reaction process, quench water recycling in the quench tower will lead to the enrichment of catalyst and a small amount of oil in the reactor.

The catalyst acts as a bridge to form large particles, which will wear and block the pores, and cause the water treatment system to paralyze.

Therefore, in response to the above two phenomena, JIUWU HI-TECH has developed ceramic membrane separation technology to purify quench water and washing water, which effectively solves the problem of catalyst and emulsified oil blocking equipment in the water system.

Process description

In this process, ceramic membrane cross-flow filtration technology is used to efficiently remove catalyst and emulsified oil impurities in quench water and washing water.

The feed of quench water and washing water is sent to circulation pump through feed pump and then enters ceramic membrane device.

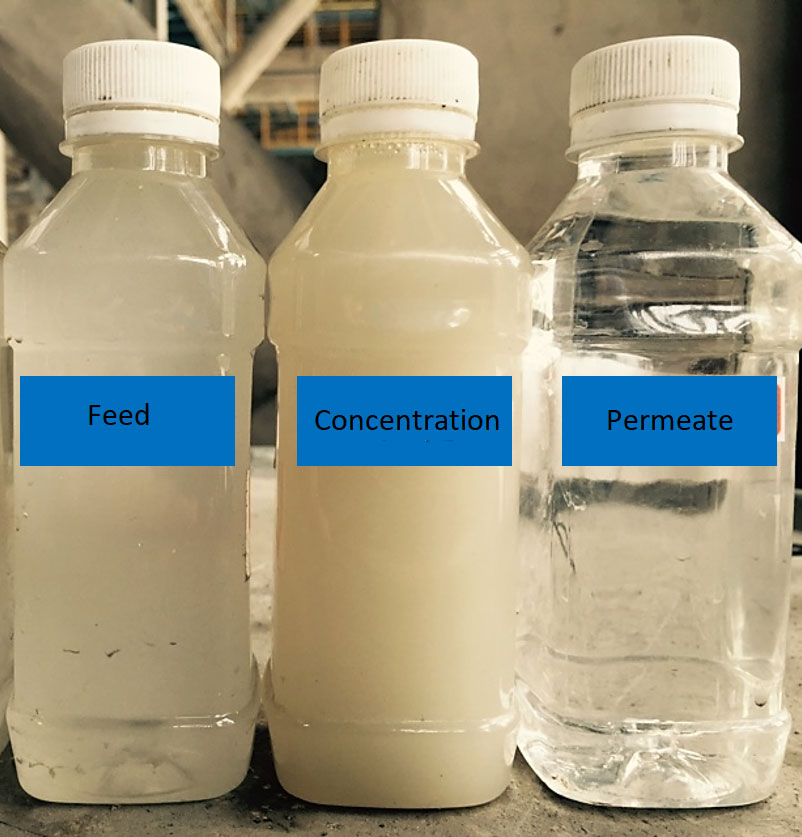

The feed flows at high speed in the flow channel of membrane tube, the catalyst and emulsified oil are trapped in the concentration by ceramic membrane, and clarified permeate passes through the ceramic membrane under pressure to enter MTO water circulation system for continued use.

After centrifugal separation, the concentration containing the catalyst is filtered through filter press, and the filtrate re-enters ceramic membrane system for recovery and treatment. The oil-bearing concentrated liquid is sent to the system for incineration because of its high calorific value.

Ceramic membrane has high filtration and separation accuracy and excellent purified water quality which completely solves the influence of impurities in the quench water and washing water on the MTO water system equipment, avoids the blockage of the tower-tray, heat exchanger and air cooler and other equipment, and greatly extends the operating time of the equipment , reduces the frequency of equipment cleaning and improves the stability of the system.

Features

High separation accuracy & completely remove the impurities.

The catalyst powder and emulsified oil in quench water and wash water can be completely removed by using ceramic membrane with pore size 50nm. The separation efficiency of catalyst is above 99%, and the separation efficiency for oils above C5 is more than 99%.

-

Simple process flow

-

Without complicated pre-treatment

-

Lower labor intensity& cost

-

PLC automatic control

-

Without expensive demulsifier and flocculant

-

Crossflow filtration , pollution resistance

-

Maintain high flow filtration

-

Excellent regeneration effect

Technical advantages

1.High quality purified water

Due to small particle size of catalyst particles, 80% of which is below 10μm, conventional hydrocyclone separator has a poor separation effect. Even the high-efficiency microcyclone separator has a separation efficiency of not more than 90%, and catalyst content in purified water is about 30ppm. The separation accuracy of ceramic membrane is as high as 50nm, separation efficiency of emulsified oil particles of catalyst particles exceeds 99%, and the content of catalyst and emulsified oil of purified water is less than 5ppm.

2.Cost-saving

Take the MTO device of Shenhua Baotou Coal Chemical Company as an example.

|

Problem

|

Solution

|

Cost

|

Ceramic membrane technology (The problem of catalyst& emulsified oil entrained in quench water and wash water is solved)

|

Cost-saving

|

|

Blockage in heat exchanger

|

Cleaning for 3 times every week

|

Four hundred thousand dolloars one year

|

annual operation cost is over one million

|

|

Xylene injection

|

Ten hundred thousand dolloars one year

|

|

Partial shutdown and tower washing treatment

|

Methanol consumption is more than four hundred thousand dolloars

|

|

|

Power consumption rise

|

3.Environment friendly & Green

In order to solve the problem of blockage of MTO water system, some companies consider switching to compressor turbine condensate instead of purified water, but this will lead to waste of purified water resources and increase the discharge of sewage. If ceramic membrane separation technology is adopted, there is no need to change the water system design, directly improve the quality of purified water, reduce the discharge of sewage, COD discharge of sewage can be reduced because the injection of xylene in the system is avoided.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español