Polypeptide is a compound formed by linking α-amino acids together by peptide bonds. Usually, a compound formed by dehydration and condensation of 10-100 amino acid molecules is called a polypeptide.

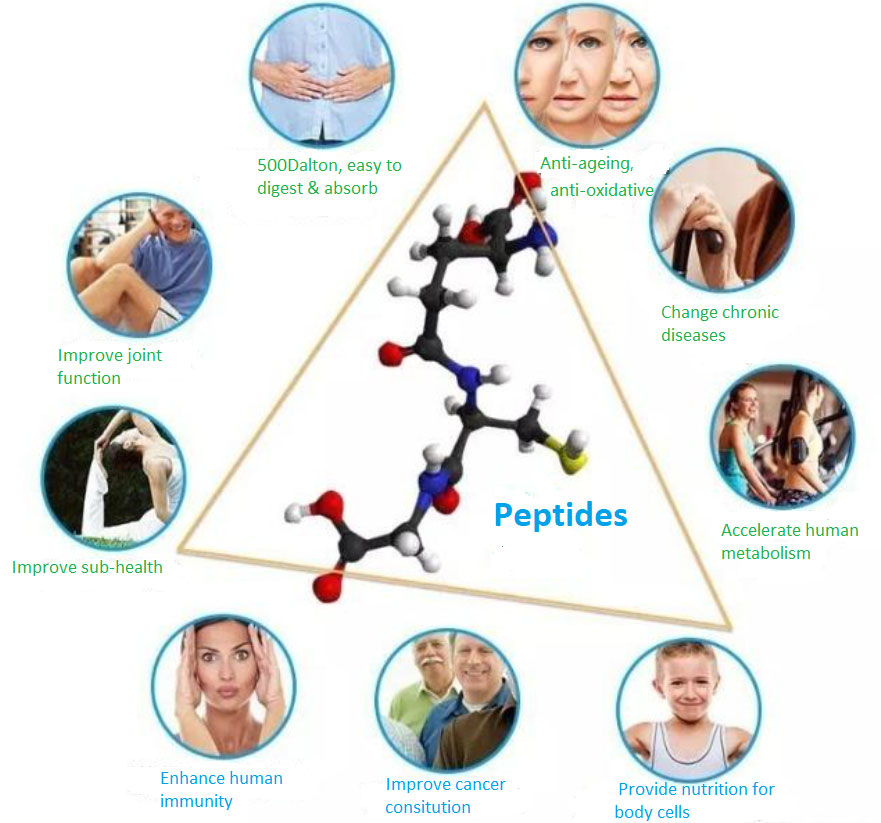

Active peptides can promote cell division, ensure gene expression and replication, and ensure that the quantity, quality and speed of protein synthesis in cells are in a normal state, thereby controlling human growth and development, aging and diseases.

Active peptides are easily absorbed and utilized. Taking peptides can supplement the lack of active substances and nutrients in the body, thereby improving cell metabolism, restoring the imbalanced internal environment, and enabling the body's various systems to work in a healthy and coordinated manner, which can not only be quickly eliminated fatigue,but also can prevent and cure many diseases, such as diabetes, cardiovascular and cerebrovascular diseases. In addition, the peptide has protective effect on myocardial cells and brain cells, and can significantly improve the symptoms of hyperlipidemia, hypertension, cerebral arteriosclerosis, coronary atherosclerosis, coronary heart disease, cerebral thrombosis sequelae, palpitation, heart distress, palpitation.

Peptides have the following characteristics and functions:

As the chief engineer of human cell conditioning, peptides are far from enough to rely solely on the body's own synthesis, especially those with impaired digestion and absorption, who need to supplement peptides to maintain normal human functions.

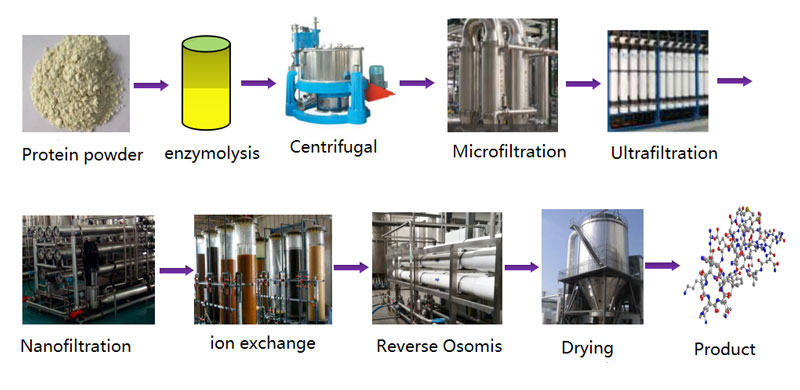

There are many methods to produce peptides in industry, mainly including: acid method, alkali method, electrical method, artificial grafting method, gene expression method, biological fermentation method, enzymatic method, etc.The method of using biological enzymes to catalyze proteins is called enzymatic method. The biological enzyme degradation method uses biological enzyme technology to obtain polypeptides through enzymolysis, degradation and hydrolysis of proteins, with a molecular weight distribution between 200-1000 Da.The enzymatic process has the characteristics of simple process, low investment, stable quality, high activity, high content and good taste of peptide products. In the enzymatic production process, the composition of the enzymatic hydrolysate is complex. In addition to peptides, it also contains impurities such as macromolecular proteins, enzymes, and ash. To obtain products with higher purity, it is necessary to remove impurities as much as possible through separation methods and enrich them. Polypeptides are finally spray-dried to make finished products with higher purity.

The traditional separation method is generally through centrifugation or rough filtration by plate and frame to remove ineffective components such as macromolecular proteins and enzymes, and then through evaporation or membrane concentration and evaporation process to remove water, and finally spray drying. The traditional process is applied earlier,relatively mature, but there are also low centrifugation or plate and frame filtration accuracy, macromolecular proteins can not be effectively removed, and at the same time, because the removal of impurities is not thorough enough, membrane concentration in the back channel is highly polluted, the flux is low, and the concentration of membrane concentration is low. It is not high enough, and multi-effect evaporation is needed to eliminate the shortcomings of spray drying.

The integrated membrane separation technology, as a separation method with high separation precision, stepwise gradient separation, and green zero addition, can meet the above separation requirements more efficiently and environmentally.

Membrane separation technology is a separation technology developed in recent decades. According to different membrane pore sizes, it can be divided into microfiltration (MF), ultrafiltration (UF), nanofiltration (NF) and reverse osmosis (RO). Separation accuracy, due to its efficient separation characteristics, has been widely used in many fields such as food, medicine, chemical industry, nanomaterials, new energy and environmental protection water treatment.

Membrane separation technology has the following characteristics:

1)pure physical process, zero addition, green and environmental protection;

2)only needs to be driven by pressure ,is simple and highly automated;

3)The separation process does not undergo phase change, which is especially suitable for the separation of taste-preserving and heat-sensitive substances

4)It can classify substances of different molecular weights, and select membranes with multiple pore sizes to form gradient filtration, which can realize stepwise separation and concentration.

As a green production method, the enzymatic peptide production process can be perfectly combined with membrane integration technology. The general process flow is as follows:

Fig 1. Process flow chart of peptides production

The effective molecular weight of peptide products is generally 200-2000Da. After proteolysis, the enzymatic hydrolysate is initially clarified by microfiltration. The microfiltration permeate is to remove enzymes and macromolecular water-soluble proteins through ultrafiltration. The ultrafiltration permeate is concentrated by nanofiltration which removes inorganic salts at the same time. The concentrated solution of nanofiltration is passed through resin to remove heavy metals. The liquid after removal of heavy metals is further concentrated by reverse osmosis. The concentration of reverse osmosis is directly spray-dried for drying and finally get the finished product.

The advantages of membrane technology in polypeptide production are as follows:

1)microfiltration and ultrafiltration membrane technology has high filtration precision. Compared with the traditional centrifugation or plate frame process, the removal rate of impurities is higher, the filtrate is clear and transparent, and it can effectively protect the membrane concentration in the later stage;

2)nanofiltration process can not only concentrate products, but also separate impurities such as ions and ash;

3)The membrane concentration has low energy consumption, which is about 1/5 of the evaporation method;

4)The whole process is simple in process, easy to operate, and achievable automatic control.

The integrated membrane technology can use a programmable process control system, supplemented by some on-site indicating instruments, to realize automatic control of the process production process. The programmable PLC system realizes automatic operation and monitoring operation, controls the production process, and controls the process parameters are introduced into the control system of the control room for centralized monitoring, thereby realizing digital intelligent production.

Fig 2. Digital intelligent system for integrated membrane technology

Conclusion: JIUWU HI-TECH has been developing and applying membrane integration technology of enzymatic peptides for more than 10 years, and has a deep understanding and rich experiences. According to different peptide molecular weight products required by customers, the separation and purification of peptides with different molecular weight can be realized by using different molecular weight membrane, which can improve the quality and yield of peptide products, simplify the process and save energy. With the increasing international influence of peptides and the diversification of development models, JIUWU HI-TECH will also contribute to the development of polypeptide industry chain through in-depth research and development of membrane materials, membrane equipment and membrane technology.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español