Graphene is a two-dimensional crystal composed of carbon atoms with a thickness of only one layer.

As a new type of nanomaterial with the thinnest, most strength, and strongest electrical and thermal conductivity found so far, graphene has outstanding physical and chemical properties such as stable structure, high electrical conductivity, high toughness and strength, and is called "black gold". It is the "king of new materials" and has been used in many fields such as electronics, energy storage, composite materials, and aerospace.

New energy is currently the most widely used field of graphene ,among which the application of graphene in lithium batteries has attracted much attention.China attaches great importance to the development of graphene industry, and has issued a series of related policies for systematic layout, listed graphene in 165 major projects of "13th Five-Year Plan".

The global graphene market can be divided into two major categories: graphene oxide (GO), graphene nanosheets (GNP) and others. Among them, graphene oxide has the highest share in the global market, exceeding 60%.

Graphene oxide is generally obtained by oxidation of graphite with strong acid.

After oxidation reaction of potassium permanganate in concentrated sulfuric acid with graphite powder, brown graphite flakes with derivatized carboxylic acid groups on the edges and mainly phenolic hydroxyl groups and epoxy groups on the plane are obtained. This graphite flake layer can be ultrasonic or high-shear vigorous stirring is exfoliated into graphene oxide, and a stable, light brown-yellow single-layer graphene oxide suspension is formed in water.

Graphene oxide needs to be separated and washed to remove sulfuric acid and impurity ions in the suspension before the final product can be processed.

However, graphene oxide is nano-sized ultrafine particles, the traditional filtration process can not achieve a better solid-liquid separation. The product loss rate and water consumption of washing process remains high, resulting in poor continuity and stability of graphene oxide production.

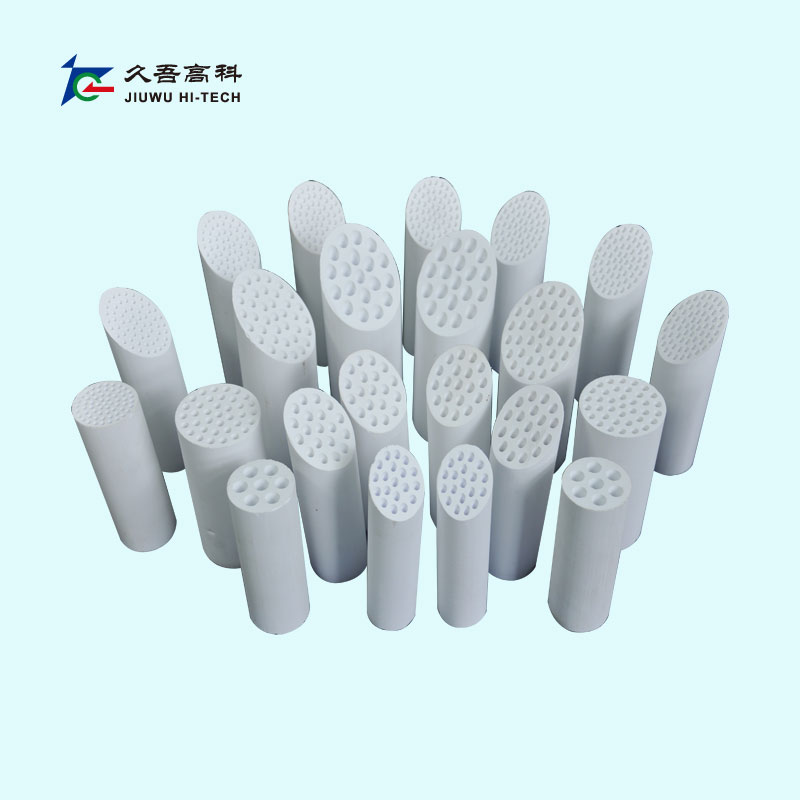

Ceramic membrane has the characteristics of high separation precision, high chemical stability, anti pollution and long life, which is especially suitable for solid-liquid separation of ultrafine particles in harsh chemical environment.

Using ceramic membranes to continuously wash the graphene oxide slurry can quickly wash the graphene oxide acid-containing slurry to neutrality, the salt removal rate can reach 99.99%, and there is no loss of graphene oxide products.Furthermore, ceramic membrane system can be further designed as a multi-stage continuous washing process, and fully automatic operation can be realized.

The graphene oxide ceramic membrane washing process has the advantages of high product retention, good washing effect, low water consumption, and high level of automation. It has been applied in a leading enterprise in the industry and has achieved excellent results.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español